INNOVATION IS OUR DRIVE

We are dynamic,

motivated and

authentic

These three aspects drive us day by day. They are the success formula of DIETL. We follow our joint goal, to improve the world of precise engineering using our quality solutions. Thanks to our extensive range of machinery, our highly qualified and highly motivated employees and state-of-the-art technology, we are able to fulfil future-orientated projects.

WE SUPPORT YOU AND CAN CUSTOMIZE YOUR NEEDS

Always close to the customer, our optimum process chain begins with our technical advice. The process continues with the development and production of prototypes and initial samples. The process is completed in end-to-end, automated series production, followed by special processes tailored to the individual parts. Our requirements are only fulfilled when the result is convincing.

Our team has the right answer for your field of business. Benefit from our technical expertise and our fresh, solution-oriented approach.

Werner Gammel and Tobias Preuhs,

Technical project coordinators

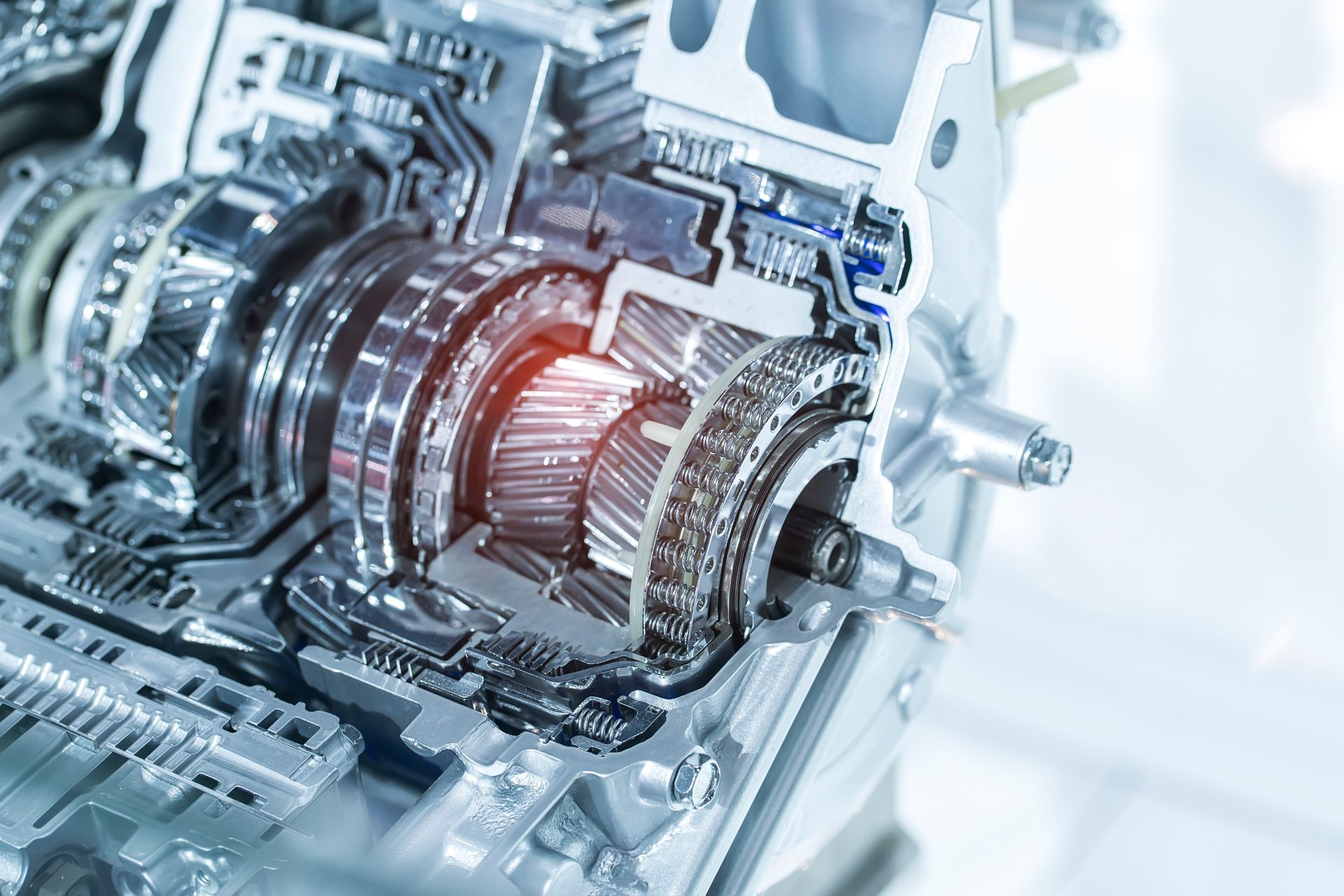

OUR PRODUCTION SPECTRUM

Precision

Know-How diversity

Micro to Macro

With our passion for high precision, we offer customers added value through a wide range of exact precision parts for demanding applications and a long service life.

MATERIALS

BEING

FULL USED

We know from experience that the right choice of materials is crucial. There are many possibilities for optimization, because it is not the properties of a specific material that are decisive here, but the intended use from the square one. This shows us the way into the future, and we are happy to continue on this path with you.

OUR COMPETENCES

Together with our

experts we tackle

any business field challenges

and never forget about trends

while doing so

CONTACT

How can we help you?

We invite you to find out more about our innovative solutions

and about DIETL.